ALPHA OMEGA PI

By ALPHA OMEGA on Jun 17, 2019

By ALPHA OMEGA on Jun 17, 2019

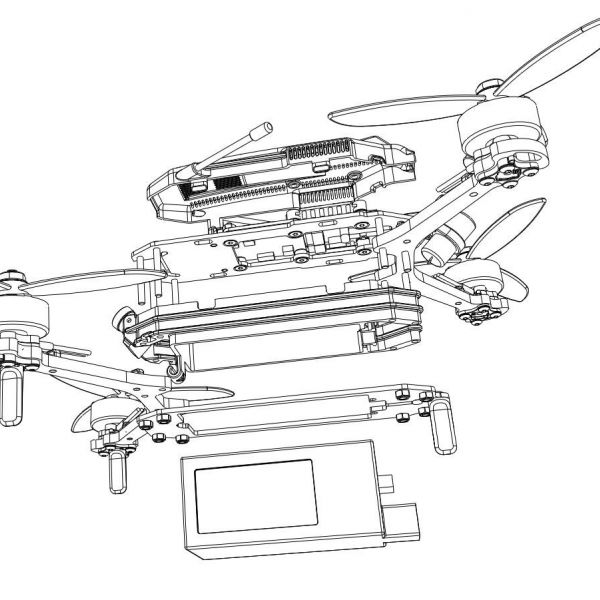

When a RC Car Designer discovers a new dimension.

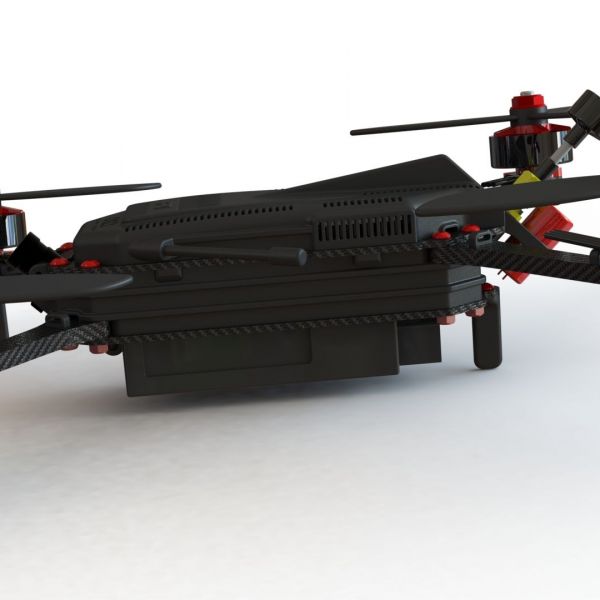

Ok, guys, I am a bloody beginner in the drone hobby - so please be gentle to me. Coming from the RC Car Racing Scene as racer and as designer, I want to make my own race drone. There are for sure some influences in design from the RC Car Racing. So I spend some time to make my own drone as good as possible - at least on the paper. I hope, I can show you the build process over the next weeks and months. Carbon parts and 3D print parts are on order - electronics are already here. Let´s see, how it comes together! Later I will explain some design aspects. Comments are welcome!

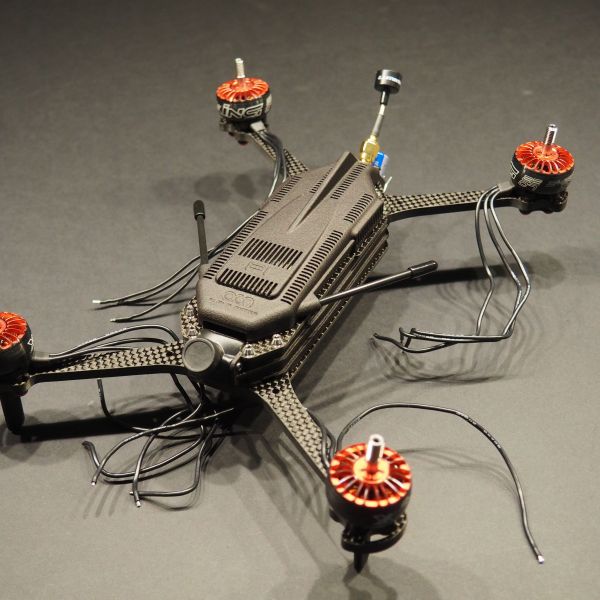

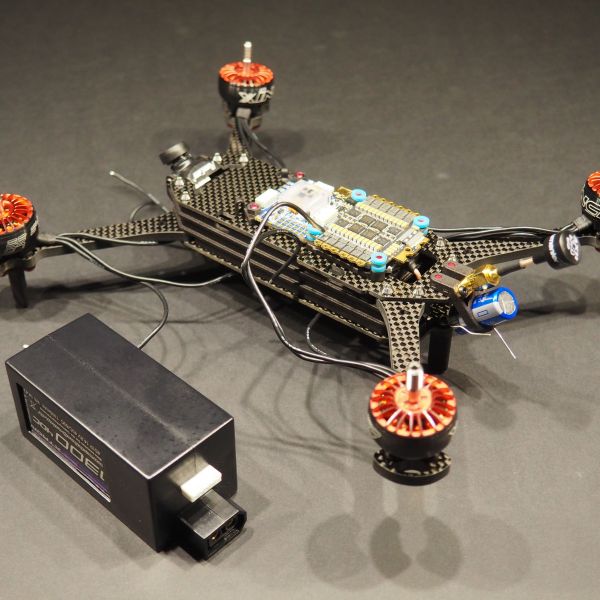

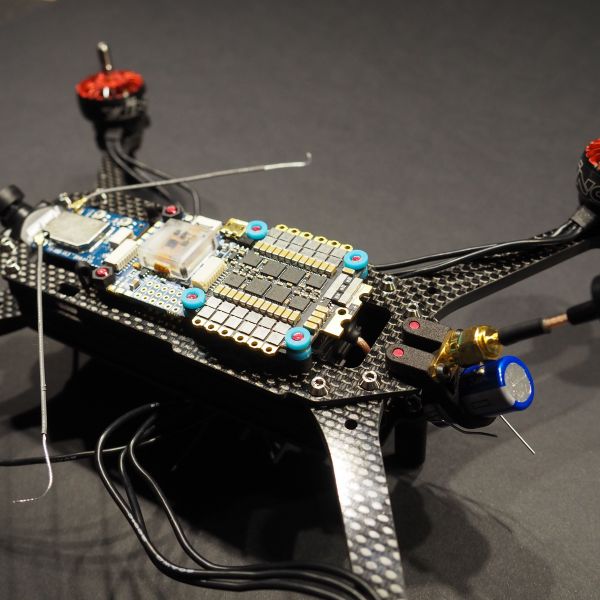

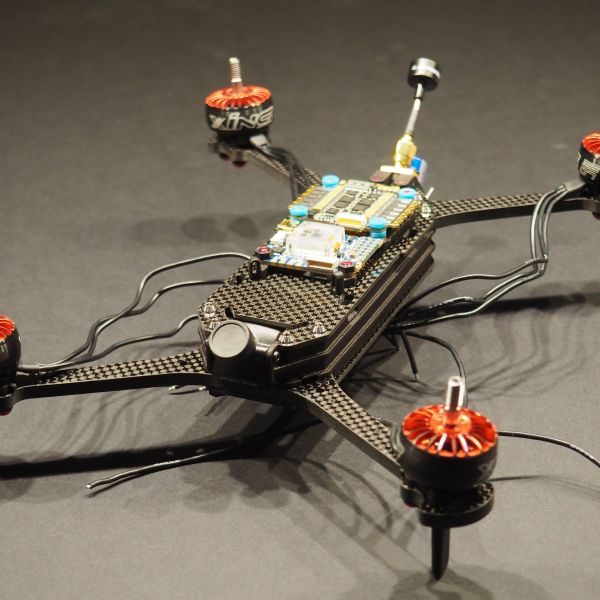

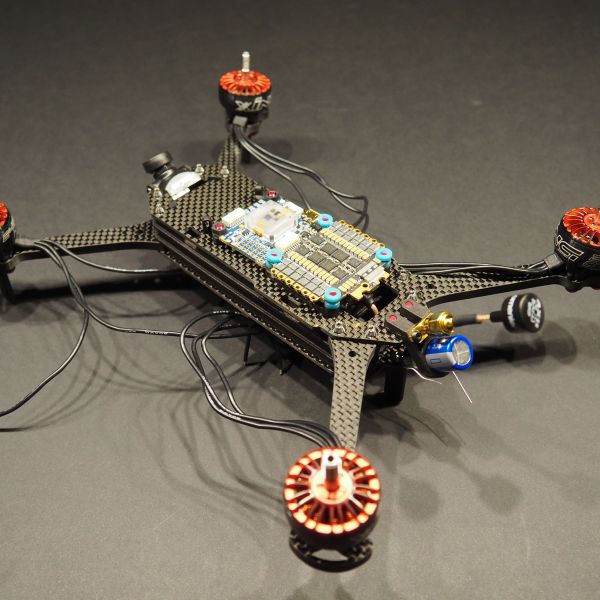

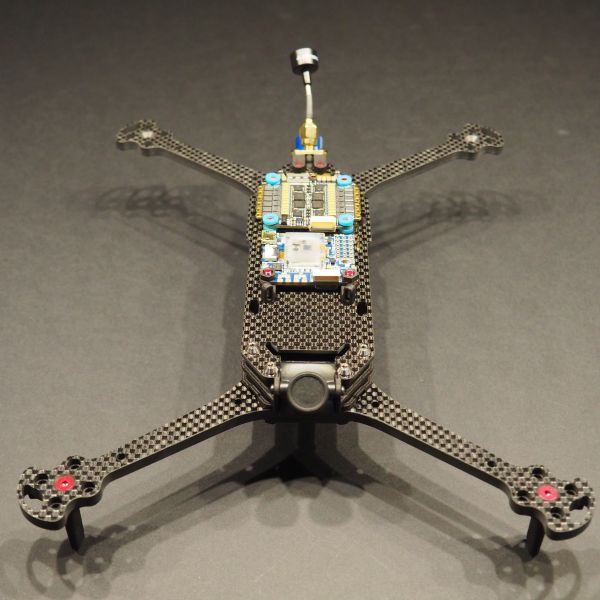

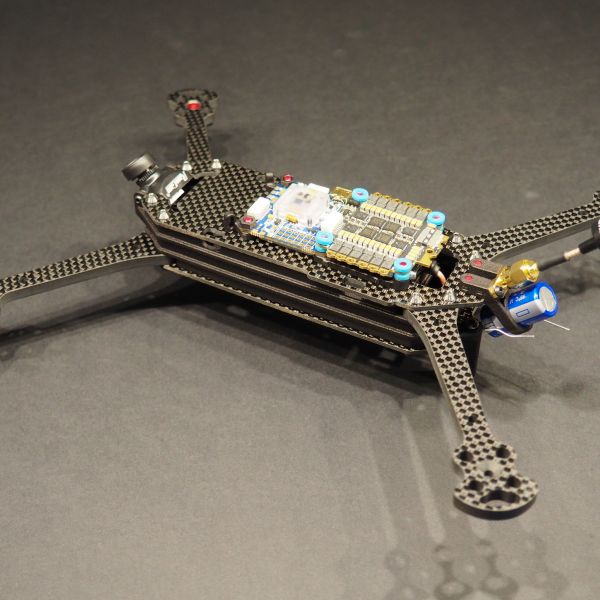

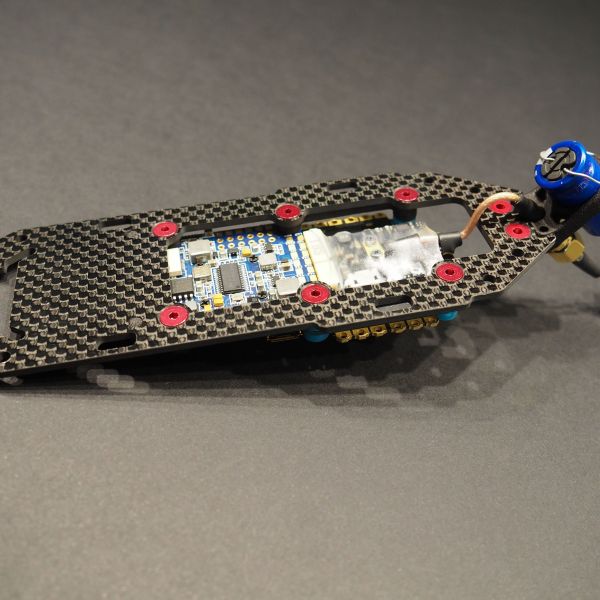

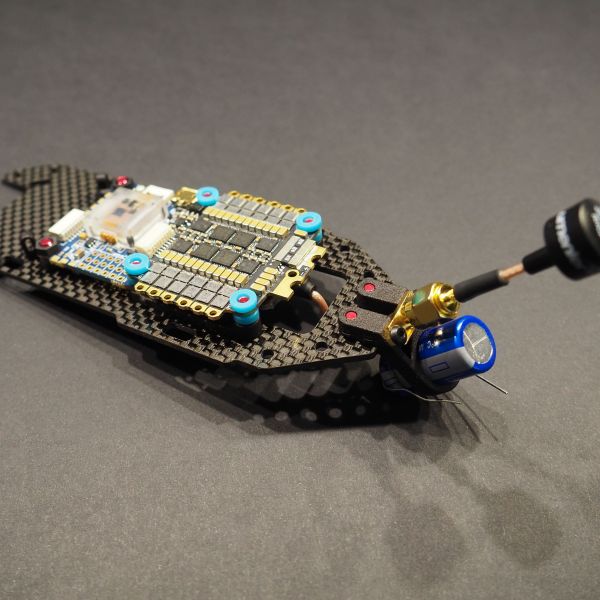

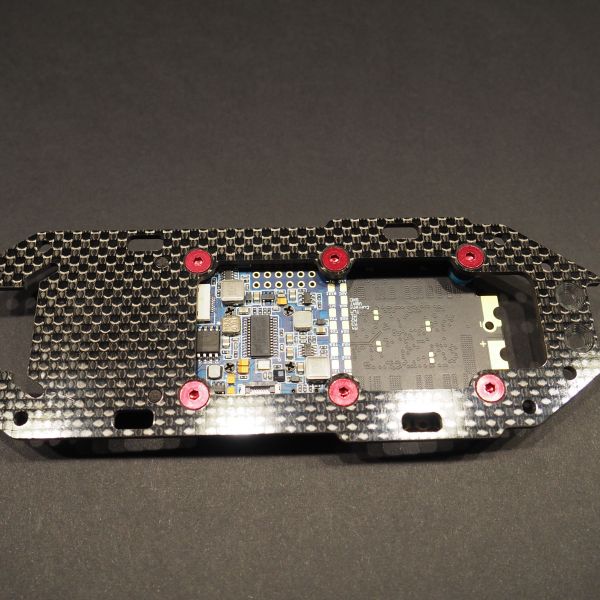

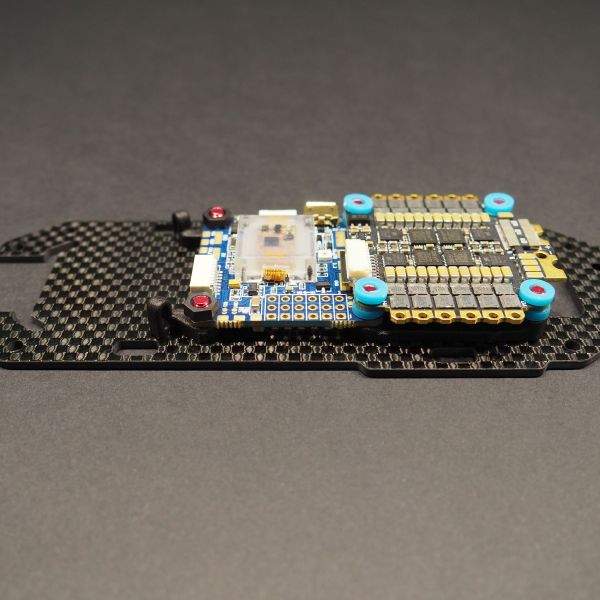

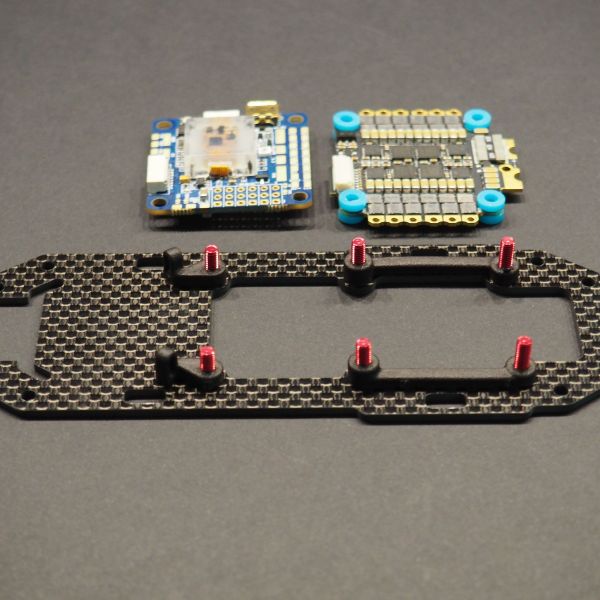

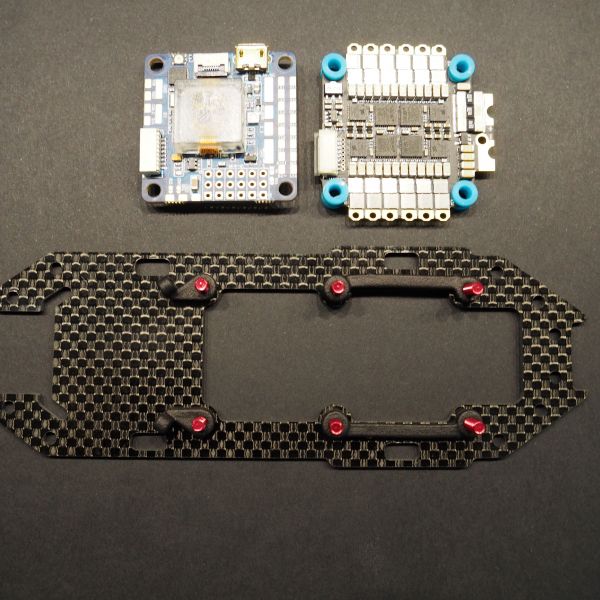

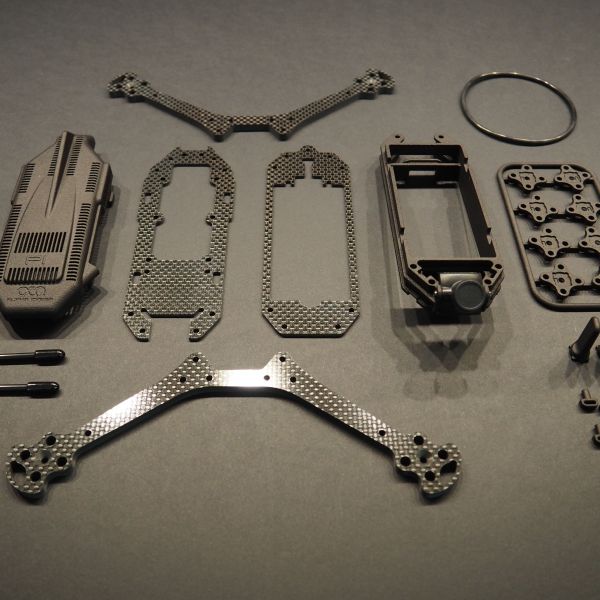

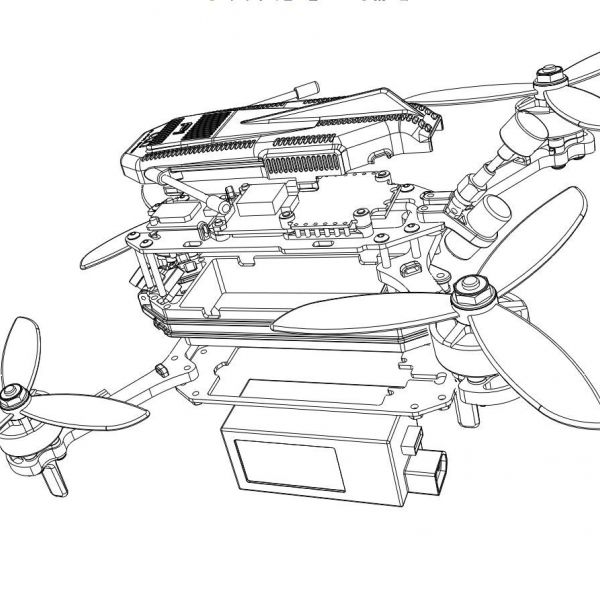

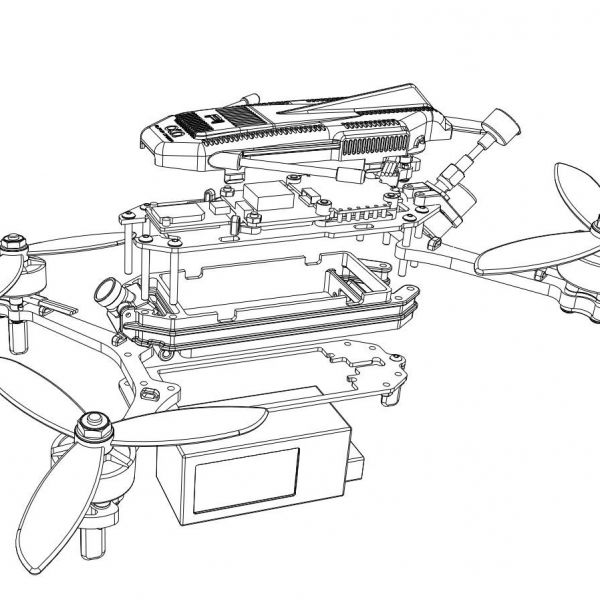

UPDATE: 3D printed parts from Shapeways and Carbon Fibre parts arrived. Today I was able to assemble the frame for a test build and check, if everything fits. And yes, it fits very well! I have put the complete frame including battery on the scale and we have 470g flight ready. Now the adventure with wiring begins! I am pretty happy with the result so far. It look fantastic in real! Thanks for your comments!

Photos

Part List

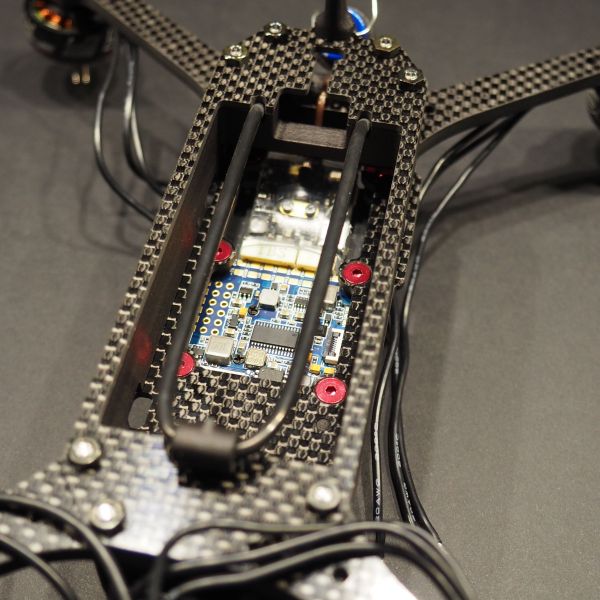

Flight Controller |

Airbot Omnibus F7 V2 Flight Controller

(2 builds)

Getfpv.com

|

$45.99 |

ESCs |

4 x Individual Drone ESCs for - RaceDayQuads

(4 builds)

Racedayquads.com

|

$39.96 |

Motors |

4 x XING X2207 2-6S FPV NextGen Motor (unibell)

Iflight-rc.com

|

$79.96 |

FPV Camera |

RunCam Racer 2

(5 builds)

Quadracer.co

|

$52.90 |

FPV Transmitter |

TBS Unify Pro 5G8 V3 (SMA)

(197 builds)

Getfpv.com

|

See Site |

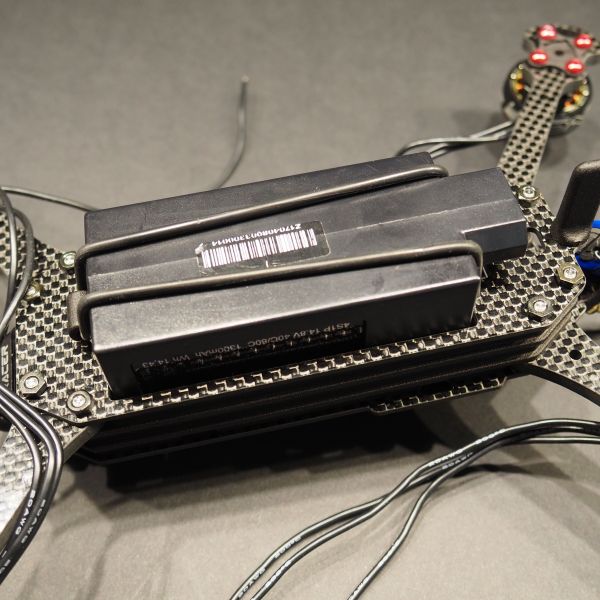

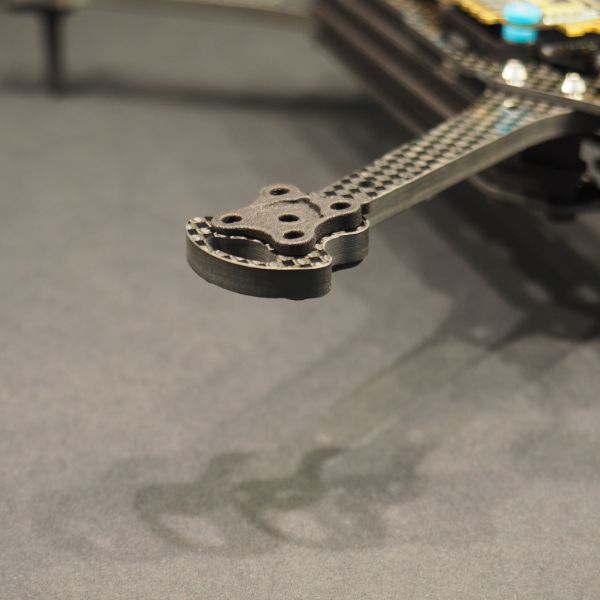

Hello there! Thank you very much for your comments! I have added some pictures for better understanding the design. I will consider all your input. But parts are on the way to me - so no chance to change things at this moment. The 3D plastic parts comes from highest quality Shapeways material (HP printer). From my experience this material is very strong, flexible and has a very fine resolution. Yes, the feet could break - but I want to give them a try. The battery is a hardcase lipo from the german brand SLS - and yes, it is probably a rebranded Gens Ace battery. I like hardcase batteries! It will be hold in place by a large o-ring. I made some guides in the main frame to hold it in place. The front/rear arms are made from one-piece, what give the whole frame a lot of durability. They are from 5mm carbon fibre material. The inserts for the motors has a 5 degree angle. You can change the position to angle the motor to the inside/outside, to the front, or to the rear. I am not sure, if this will change the flight characteristics, but this is something for testing. I also made inserts with zero degree for standard position. By the way, the 8 inserts weights only 4 grams total. talking about total weight, after my calculations this 5 inch quad will weight around 490 grams in total. Once I have everything here will will know the truth. I hope, you guys enjoy this build as I do! Please keep up your comments and all your help! thanks you!

I would never expected someone inexperienced with quads to have come up with something like this, this is so impressive. not got a lot to add to the other comments, except maybe about antenna orientation

Love the tenacious approach, jump in the deep end!

- landing gear are unnecessiary weight, and those will definitky break unless you make them WAY too heavy.

- Where are you planning to put your battery? What about straps?

- you need some part to extend out in front of your camera to keep it from getting smashed (no, the front arms aren't enough)

- The tilt on your motors are unnecessiary, and unproductive, as well as adding weight in a VERY undesirable position relative to the CG ( I know, you were hoping to add stability mechanically, to make it track straight. The software will do it so well that it will blow your mind, and you will quickly realize you don't need it. It's much more important to mount your motors securely, and the spacer there to accomodate the tilt is just in the way)

- I know it's not a criticism, but MAAAAAAAAAN that upper deck/canopy on top looks siiiiick!!!! I love the integrated ventilation, antenna mounts, and the subtle turtle mode fin!

Can't WAIT to see it built!

Quads are a study in minimilism , If we keep making them with the same materials amd techniques , they all end up similar.

The carbon fibre plate we use is not in my opinion well suited to the structures we are creating , if designed and constructed properly a 60 to 80 gram frame should be , dare i say it un brakeable.

Good work

if i'm not mystaken thats a hardcase battery on the bottom https://www.genstattu.com/tattu-1300mah-14-8v-75c-4s1p-hardcase-lipo-battery.html

the arms dont look like they have enough material suppoting them where they attach. it might be a good idea to look at other frames and see what they do well. also thnk about what your doing differently to other frames.

Little update for you guys!