technique ultralight 1102 setup

By matthew saigon on Nov 27, 2019

By matthew saigon on Nov 27, 2019

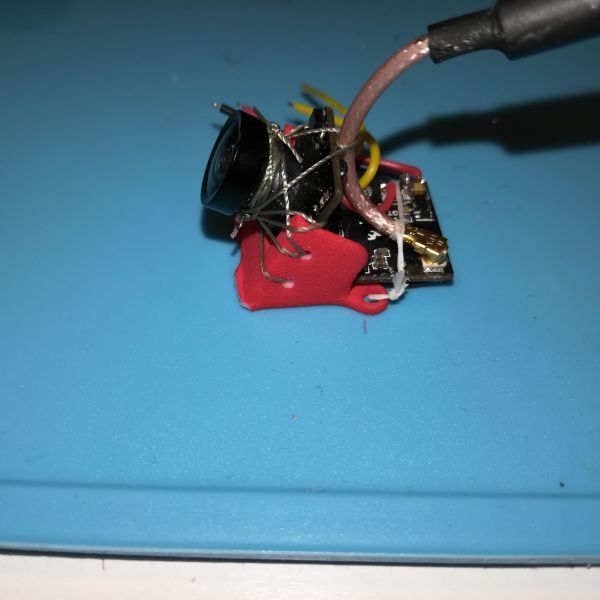

12/10/19: ( in the picture ) i'm testing out filament tape. the one they wrap around batteries. i think they're very strong. they can hold everything together. they're weightless, so wrap as much as you want :)

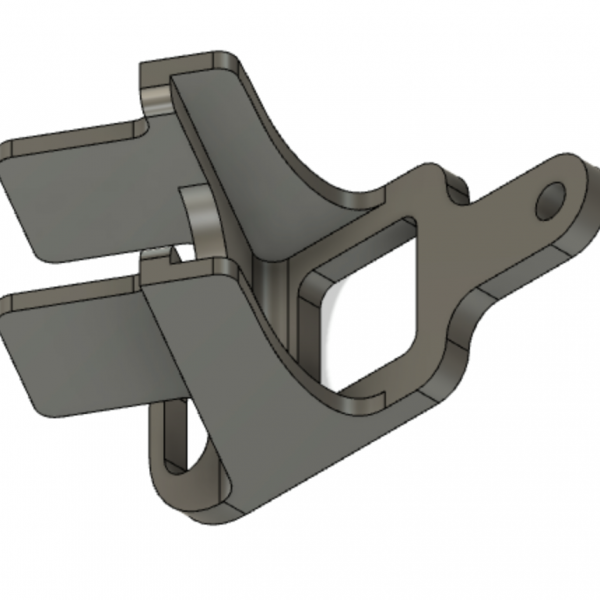

12/6/19: i just asked Alexandre Arvinte to design a canopy for my experiment. it'll be printed in ABS. i hope it'd turn out good. ( picture and link )

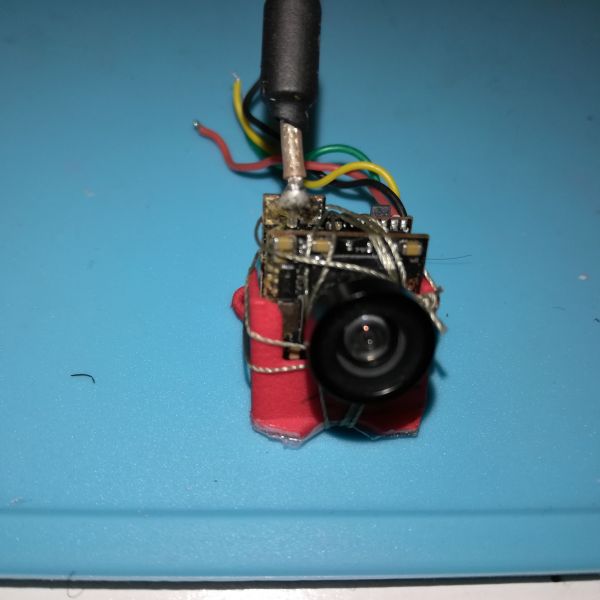

12/1/19: so i tried to use separate cam and vtx without adding any weight ( in the picture ) and it worked out fine. but to add receiver it will add 2 grams to the setup which i'm not going to since i don't go anywhere far. but in the picture i show you where to put it. basically, you put foam tape ( industrial strength ) on both sides and stick it to the front of the camera and use electrical tape to wrap the receiver and everything together ( front to back ).

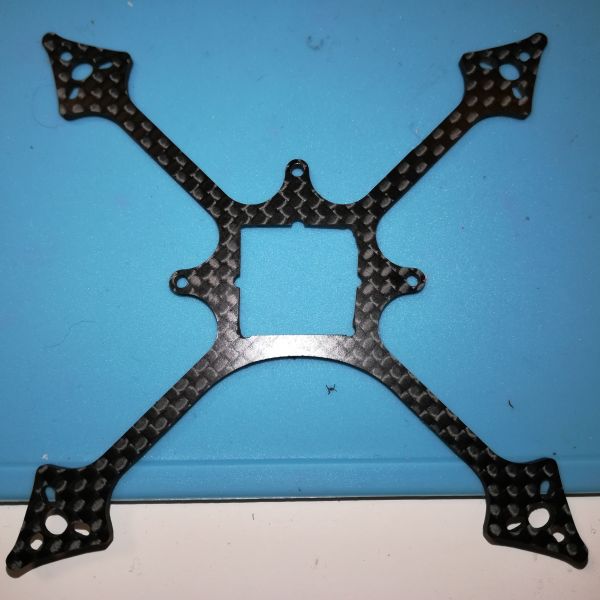

-- i also cut out the center of the frame a little bit. frame is now a bit lighter and still feels the same as the original.

this page is about a technique to build super light 1102 setup.

if you want the details of the setup then go to my 3s 1102 page.

this technique is not necessary but just for fun.

it would save 2 grams from normal newbeedrone canopy toothpick style setup which is nicer and easier to build.

and sure, someone will show up with a lighter build with 1.5mm thick frame. but i don't like 1.5mm thickness, even with 0802 motors.

i'm trying to perfect my little speed demon 3s 1102 8500kv kk65mm props. i'm trying to keep the weight down as much as possible. i used a upholster sewing thread to tie camera and canopy together. used foam tape and stick it on the board. used electrical tape to tie camera, canopy and board together. and then used foam tape to stick them to the frame. and then installed and soldered motors. and then used rubber bands to hold the fc board in place and also doubled as battery strap. also used 2 pieces of lite ummagrips for battery pads. result: save 2 grams from normal newbeedrone canopy setups normal builds look nicer and easy to build. this is just stupid but challenging and fun to build.

i think those pictures are self explained enough. but if you have question, just shoot me a message.

i used upholster sewing threads. they're strong.

stuffs used:: upholster sewing threads, foam tapes ( industrial strength), electrical tapes.

the foam on top of the camera i think i got it from happymodel motor box but i'm not sure.

and i think i used stuffs from hardware stores. no special stuffs here :)

make sure the camera installed right and straight. or it will take a long time to take the whole thing off.

11/28/19: the last 2 pictures are for the next challenge. 32g with frsky r xsr receiver and also 33g with both r-xsr and vtx.

New Message for matthew saigon