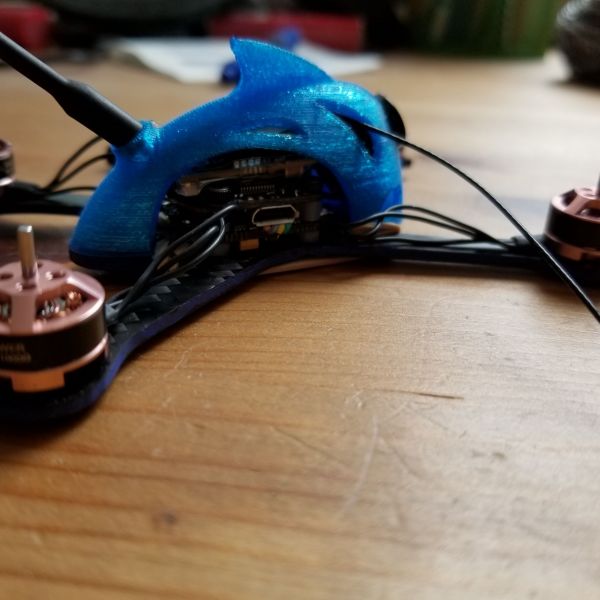

Babyshark micro

By UpMostBeast FPV on Apr 15, 2018

By UpMostBeast FPV on Apr 15, 2018

Update

The ewrf e7082c is a crappy vtx. It overheats causing black lines and snow in the video. I replaced it with a TX200U from piroflip which works great. Also I leaned up the build a bit and shaved some grams to bring the dry weight down to 47.6g. Here is a flight footage. There is a bit of jello and I am going to try some cyclone q2035c props to see if that takes care of it.

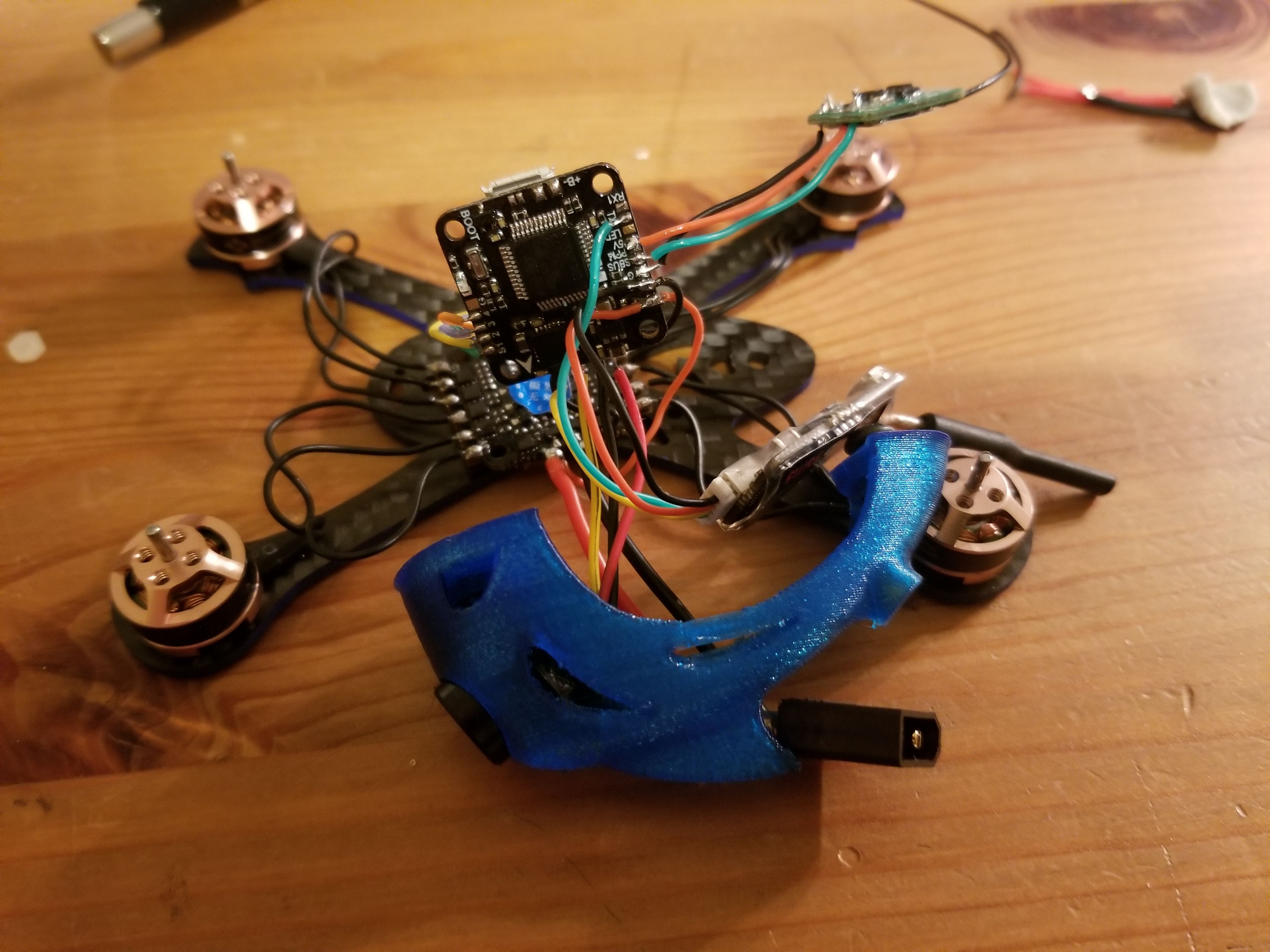

Frame

This is a 2 inch babyshark from falcon multirotors that runs on 2s. It only offers 16x16mm mounting holes and designed around the generic 600tvl micro fpv camera from banggood.

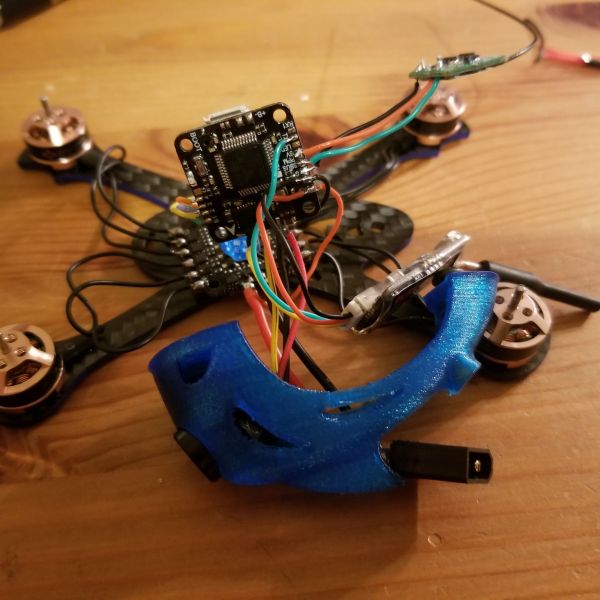

Motors and Props

I chose the airblade 1103 10000kv for good power on 2s that won't be killer on the amps. These are paired with gemfan 2040 Hulkies that are supposed to be quite efficient which suits the electronics I have in this build.

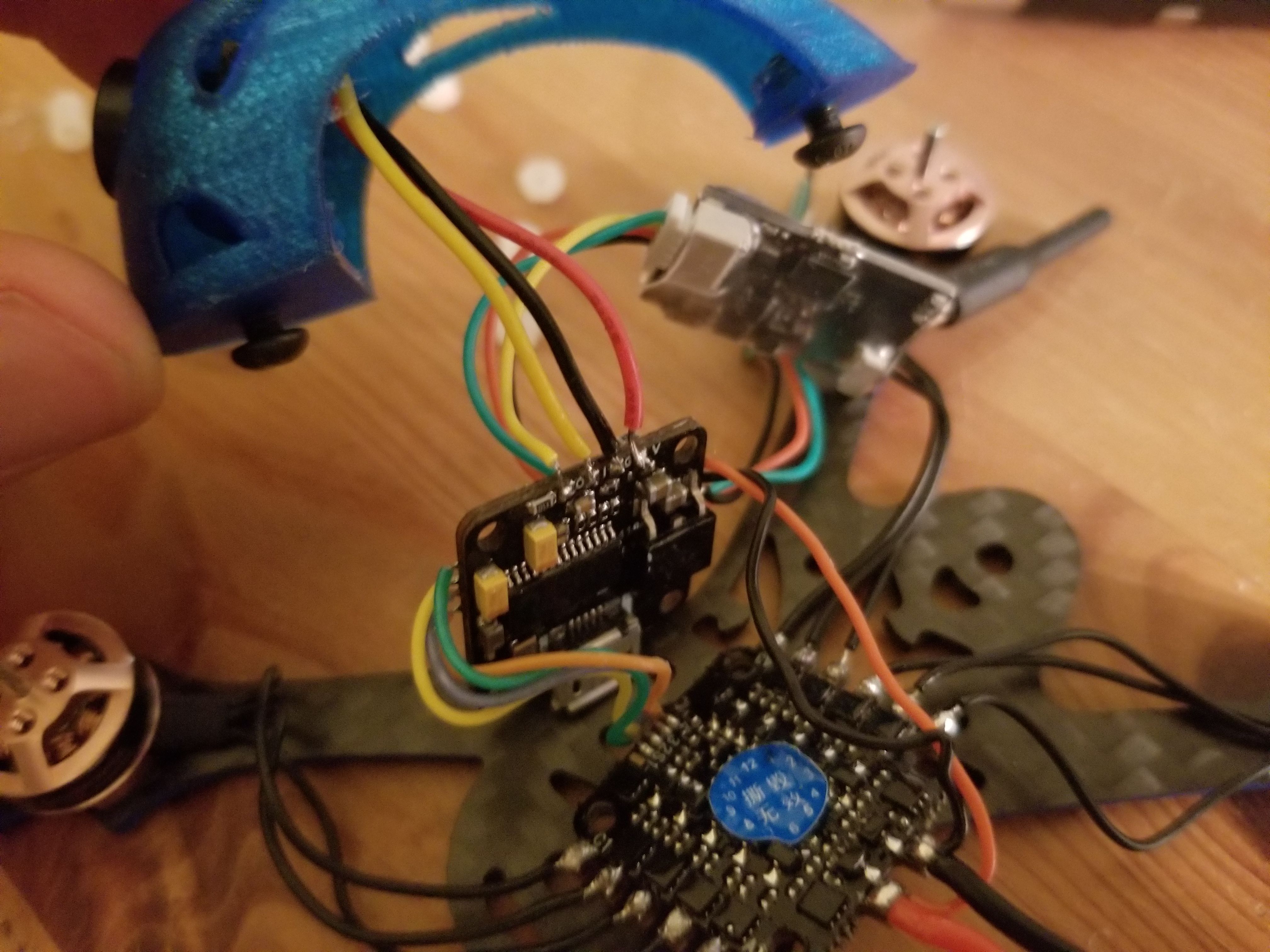

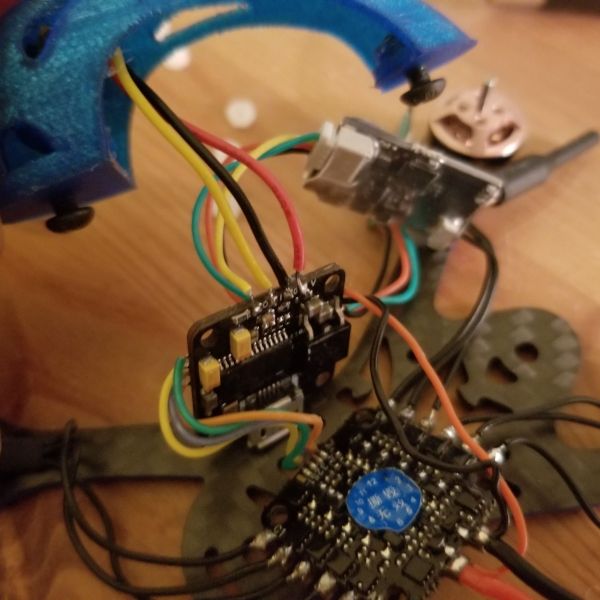

Electronics

I used the 16x16 flight controller and esc stack from airblade. The esc's are rated for 5A but this has not been a problem so far with the gemfan hulkies. The fpv camera is the generic 600tvl camera from banggood. It fits snug within the tpu mount and there is no need for glue or tape. The vtx is a cheap light one from banggood that features smart audio. This will be nice since the build is so tight and I don't want to have to take it apart to change any settings. I used a xm since I wouldn't be looking for much range on this build and it is so small and light.

Build Process

I started by mounting the motors first with locktite and then began soldering the vtx and receiver connections to the camera. I had to take apart the stack from airblade to get access to the camera and video transmitter pads on the underneath of the flight controller. This was a pain in the but as the nylon nuts were incredibly difficult to unscrew. I mounted the flight controller rotated 90 degrees so that I could have usb access after completeing the build. Before soldering the camera, I put it inside the canopy. but before that I glued down the m3 nuts that were included within the frame kit to the inside of the canopy else the would rotate freely and I wouldn't be able to unscrew the canopy mount. After mounting the camera I then soldered in to the board and then I soldered the motors to the esc. Once all the soldering was complete, I conformal coated all the electronics.

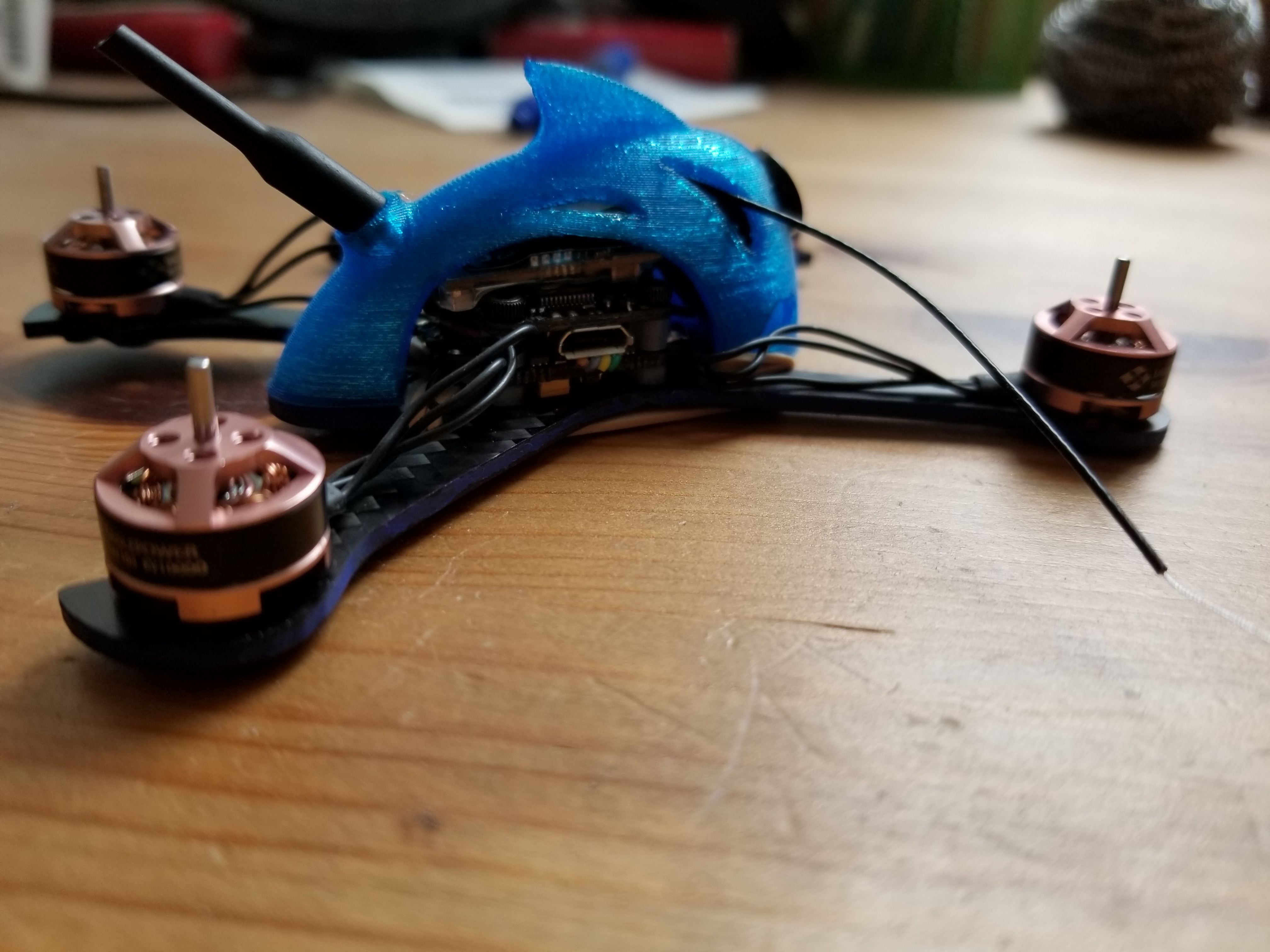

Now that everything was soldered I put the stack back together with the nylon screws from the kit, stuck the vtx on top of the stack and taped the receiver ontop of the vtx. However, after putting everything together, I plugged it in and found that I had mounted the fpv camera upside down. The dry weight of the quad at this point was 44.6g.

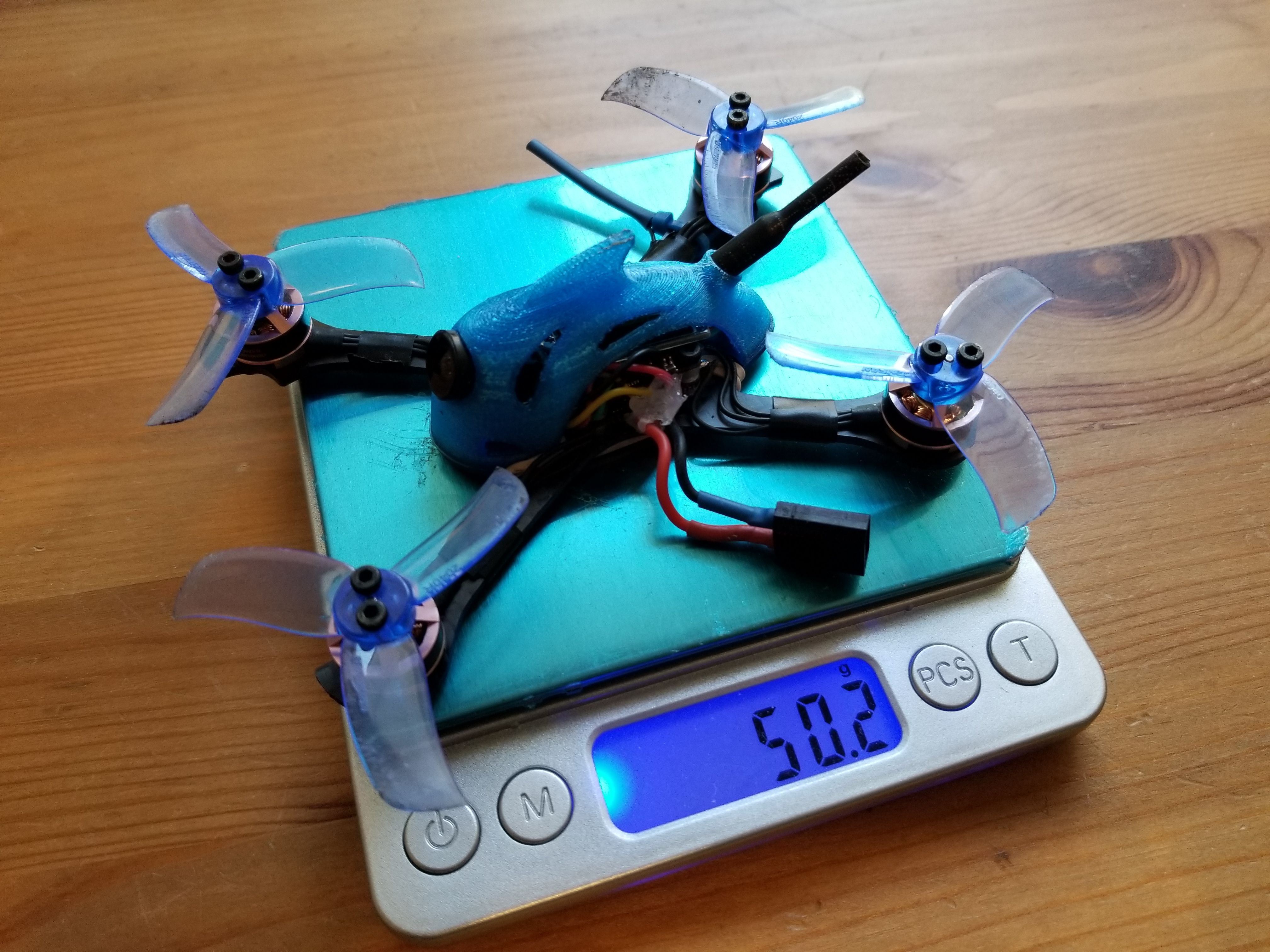

To fix the camera, I took apart the quad and pulled the camera out of the canopy. After flipping it and reinstalling it, I had to resolder some of the camera wires. They are fairly fragile and can't take a lot of tuggin on them. After being fed up with the difficulty of the nylon screws I then switched them out for some metal ones i had from an m2 hardware set and put the copter back together. Everything worked at this point. I then taped the motors wires to the arms, mounted the receiver antenna with a ziptie and heatshrink and shorted and heatshrinked the battery lead to sav some weight. Since I broke the camera wires will building the quad and had to do some tricky soldering to fix them, I hotglued the the wires and the battery lead to provide some strain relief. The final weight of the quad was 50.2g. This is heavier than some other babyshark builds which I believe is due to the heavier motors and vtx that I used. Plus the metal screws for the stack and the stack itself is not as light as the fishpepper stack that is popular for this frame.

really cute

Thanks! It is one nice looking frame that's for sure. Though I am having some video problems uunfortunately :(.