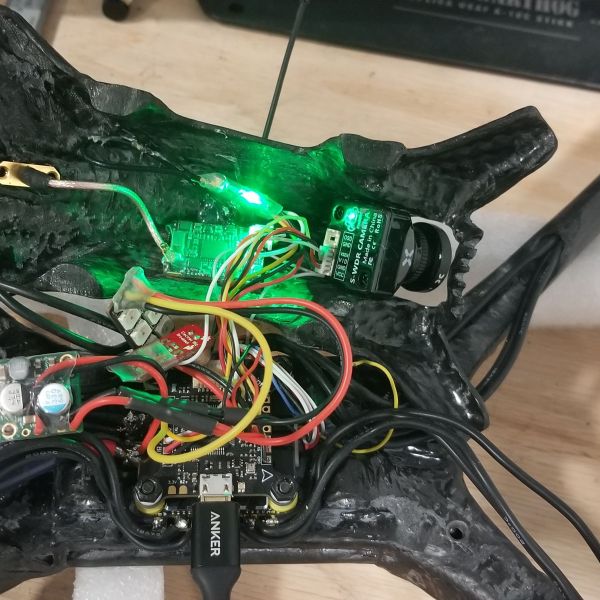

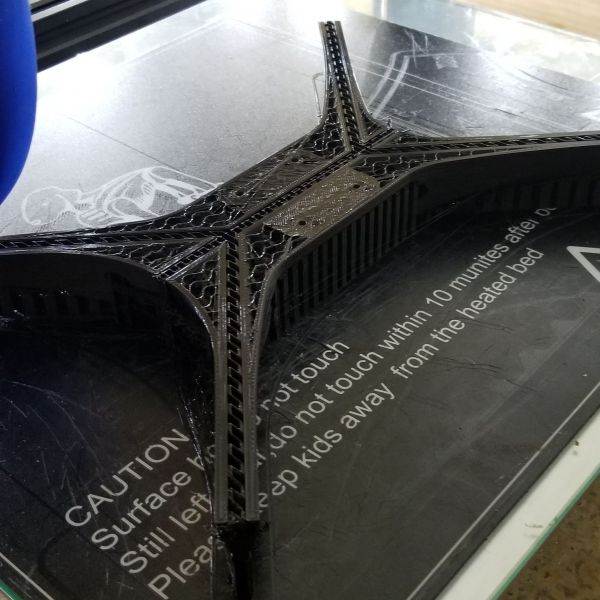

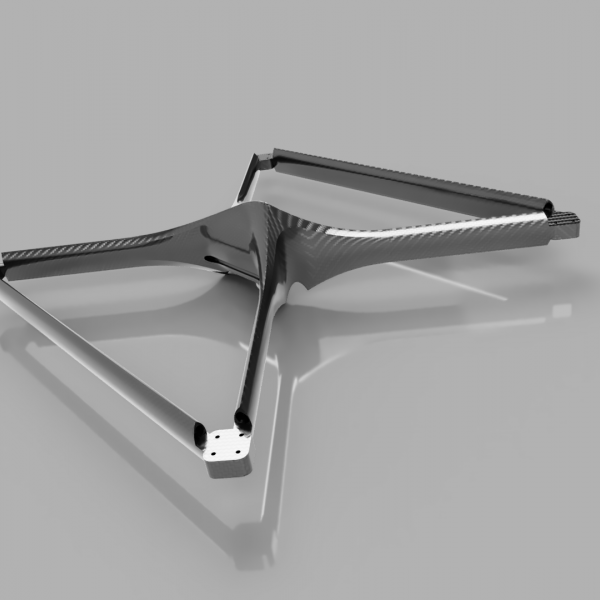

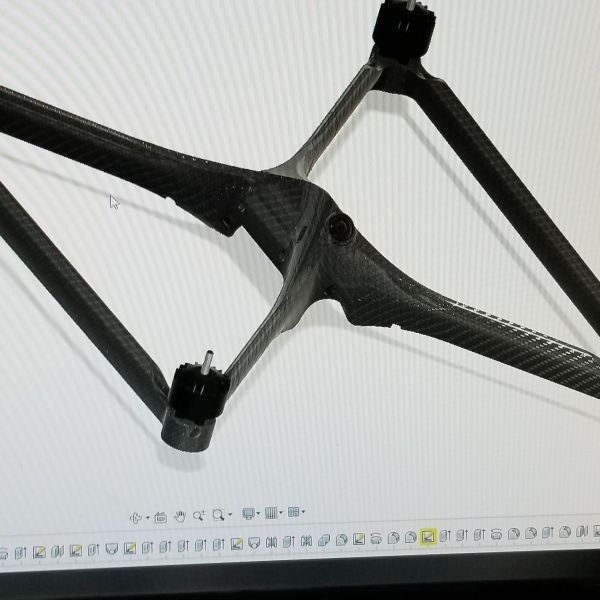

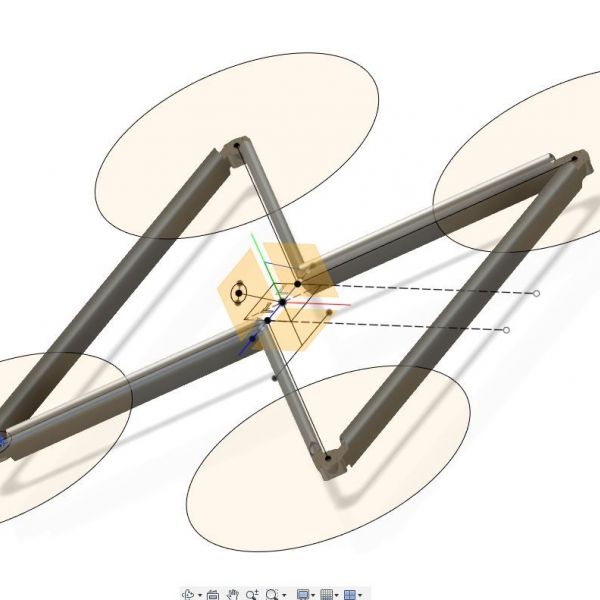

I designed and built this beast class quad to figure out how I want to proceed with my Xclass build. I designed the frame in Autodesk Fusion360. I 3D printed most of the body and then reinforced it with carbon tubes and wrapped the body with carbonfiber sleeves. I initially was going to use 4 esc's and a pdb but one of the esc's was bad and switched to a T-55 4in1. I learned a lot from this first build and designing my Xclass with that knowledge. Flight test went well, just need to calibrate the amp draw. Weight without battery is 1131g

Aloha!

Photos

Part List

Show stores (12)Hi. Did you use prepreg carbon sheeting . if so where did you get it.

Cheers.

I mostly used carbon sleeving with either heat shrink wrap or vacuum bagged it. You can find the sleeving here: https://www.sollercomposites.com/CarbonSleeves.html This stuff is awesome for building with.

Theres a way to make prepreg, I have a friend that builds boats that is going to teach me.

Guides & Reviews

AirbladeUAV has done it again and this time they've brought long range to the 5" class! Based on the popular Transformer Mini, the new Transformer 5" Ultralight adopts a lot of the same design philosophies with larger props and more payload capacity. It can fly upwards of 20 minutes on a 4 cell Li-Ion battery pack and in ideal conditions it's got a range of over 4 to 5 miles. In this guide I'll walk..

Read moreWith the release of the DJI FPV Drone cinematic FPV has become a lot more accessible, but you certainly don't want to crash a $750 drone! The QAV-CINE Freybott is a compact, lightweight cinematic FPV drone that can take a hit and keep going. It's a lot safer to fly indoors and around people. With a naked GoPro or the SMO 4k you can capture some great stabilized footage. In this guide I'll show you..

Read more

I love what you're doing here.

The contour you put on the brace that runs between the motor mounts makes sense in a way that it couldn't if you put it side to side inbetween the front motors, but I wish you could get the strength there.

The 3d print as a pattern to lay your carbon on is so aweseome.

I see the way you need a modular section for your boards, and camera, but I kinda wish it dropped down out of the bottom, in stead of taking the top off like that. Mostly for aero concerns from the seams/gaps.

I want you to do it again, really a few times. The same design, just do it till you get really familiar with the material. A slick finshed version of what you have here would be a real winner. I honestly think what you HAVE is great. I imagine you might have some ideas about how to do it better structurally (just in terms of how you want to embed the tubes, and connections between long parts). I would watch a video series detailing every step of this process if you put it on youtube.

Thanks! My Xclass design has the brace the way you describe it. Slowly working on that one incorporating the lessons learned from this build.

The gaps in the top cover were because I had 4 ESC's that were pretty big with the capacitors. I had cut open the frame to fit them.

While I'd like to make it super sleak, I still need to have airflow over the electronics for cooling. I'll be designing in vents on the Xclass.

I'm pretty shit at documenting my process, work and life often getting in the way. Plus always going broke buying materials!

I can't wait to see the next one!!!!!

working on it....