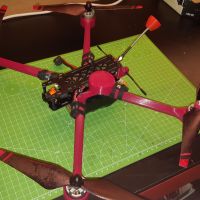

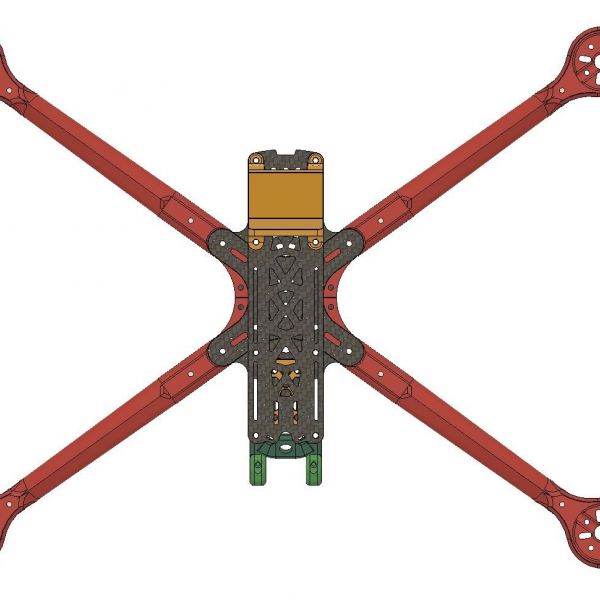

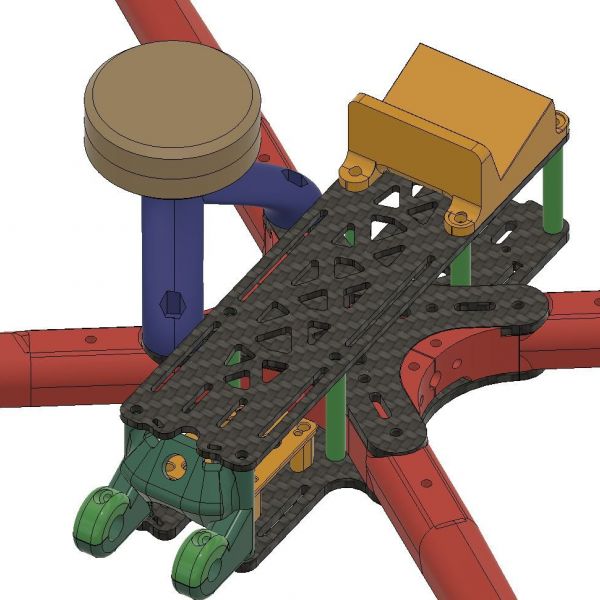

Huge, 9.4" quadcopter frame based on TBS SourceOne frame elements and typical racer parts.

It uses DJI Phantom II motors/propellers because of it popularity and price. I have never expected DJI 2312 motor designed fo 4s will handle 5s or even more voltage. Tune PIDs, make sure motors will not become hot becouse of vibrations or bad FC tuning and it will work fine with a heavy load.

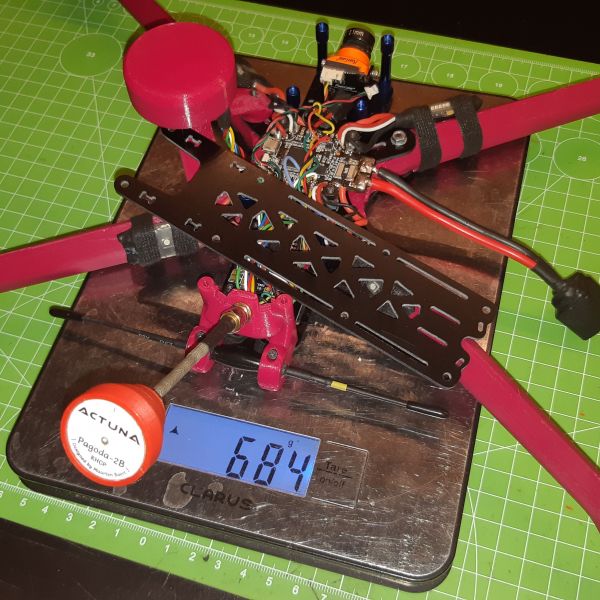

Quadcopter created to fly long and far on LION batteries, my slightly lighter setup (same electronics) last year was able to hover 55 minutes using 5s3p battery (12Ah+). Typical flight time on 5s1p is 25 minutes, 5s2p gives 35 minutes. Older arms have been made of woods (dry oak ;-)). Current RTF weight is more than 600g, 5s2s LION adds another half of kilogram, so make sure you will fly securely for other people (far from them). This will harm others just like X-class when have the speed. But the sound of heavy loaded ~10" props ... is amazing, believe me.

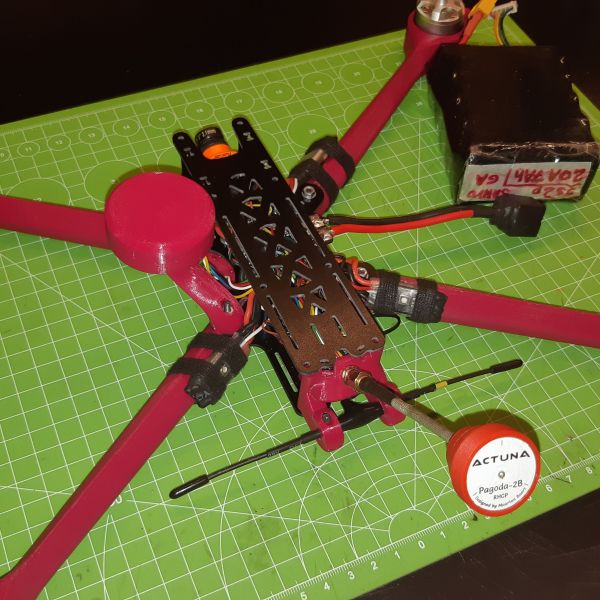

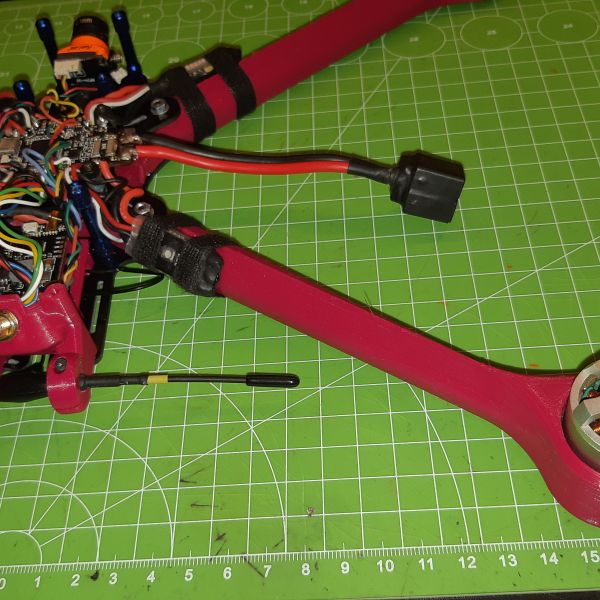

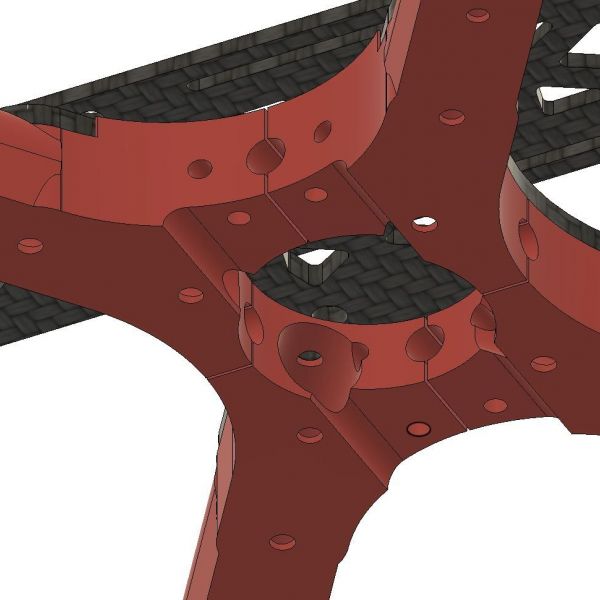

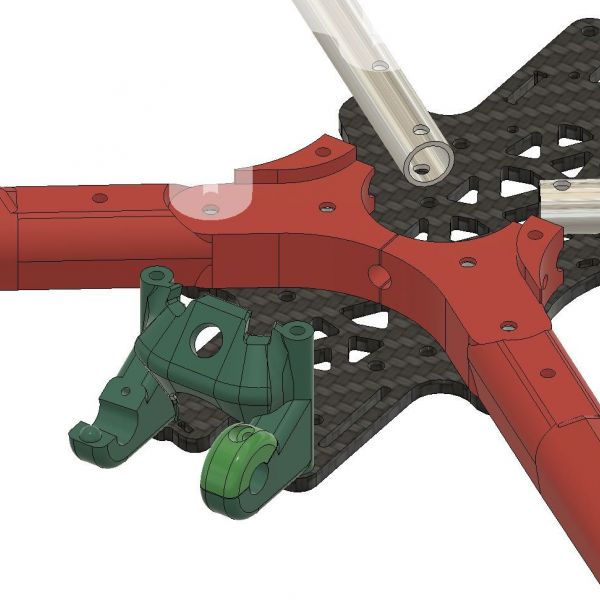

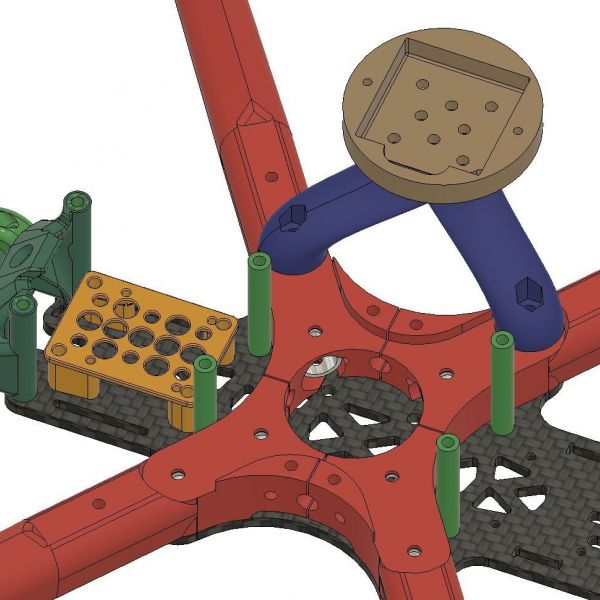

Pictures taken for prototype arms, current design has been improved and optimized for non-support 3D printing.

Arms has a space, a tunnel for motor and LED cables inside aluminum pipes, also central arm mount has holes to lead this cables to the ESC.

I expect I will improve it in the future

- ESC cover and mount

- arms to handle regular 10" props or other motor

- ... you tell me

Build a bit 'under construction', but ready to share and comments ...

I. FIRMWARE

- Recommended iNAV

- because of outstanding GPS support, waypoins mission and RTH capabilities

- https://github.com/iNavFlight/inav/wiki

- https://www.youtube.com/user/dzikuvx

- BetaFlight will work also

- but why to use it ?

II. FRAME and PRINTED PARTS (thingiverse)

https://www.thingiverse.com/thing:4379953 (wait a day or two, if not available yet)

- Bottom, center and top plates taken from TBS SourceOne v0.3

- in my case plates are not 3mm thick, but CAD design assumes carbon is 3mm

- the assembling is not as designers expected (bottom plate is at the center)

- it should be possible to assemble the arms below the cage

- 3D PET-G printed arms with aluminum pipe reinforcement inside

- quadcopter will work fine even without aluminum pipe, but it is better to have it inside PETG arm

- it is possible to increase thickness or put carbon reinforcement of different shape inside

- motor and LED cables goes inside reinforcement pipe in the middle of arm to center of frame

- aluminum pipe diameter is 10mm (1mm thickness)

- Custom designed 3d printed mounts

- pigtail VTX & RX antenna mounted to top plate

- pigtail VTX & RX FrSky r9mm antenna

- rear midplate for RX or other parts

- side GPS mount and BN-880 GPS/Compas case

- HD camera 'coach type' mount

As usual assembling requires M2 and M2 screws, nuts and washers.

III. ELECTRONICS (no matter what is inside if you know how to assemble the racer)

- Matek F405-CTR

- iNAV support, barometer inside FC board

- it is time to go to F7 now, but this FC has a plenty UARTs and no problem with (un)inverted F.Port mess

- http://www.mateksys.com/?portfolio=f405-ctr

- DJI Phantom 3 motors

- 2312 960 KV perfect to 10" props

- popular, cheap and effective with oryginal 2-blade props

- takes no more then 25A at full throttle in 4s, I was surprised how optimal those motors are in that setup

- https://www.buildyourowndrone.co.uk/dji-phantom-2-2312-motor-cw

- DJI Phantom II 9.4" propellers

- required by compatibility to DJI motors above, there are better and more expensive replacements if standard props are not good enough

- in my opinion props should be stiffer, by it was not designed for race ;-), good idea to limit throttle in iNAV

- https://www.amazon.com/DJI-Self-tightening-Propeller-Professional-Quadcopter/dp/B013256K0I

- HAKRC BlHeli_32 35A ESC 5s with LEDs

- has integrated LEDS so I mounted on arms at angle

- https://www.banggood.com/HAKRC-BLHeli_32-Bit-35A-2-5S-ESC-Built-in-LED-Support-Dshot1200-Multishot-for-FPV-RC-Drone-p-1277587.html?cur_warehouse=CN

- Eachine TX805

- BEITIAN BN-880 GPS & Compass

- you need compas because of iNAV features, it has to be mounted 'far' from other electronics to make sure compas will work fine

- https://www.banggood.com/UBLOX-NEO-M8N-BN-880-Flight-Control-GPS-Module-Dual-Module-Compass-p-971082.html?cur_warehouse=CN

- FrSky R9mm receiver

- just to make sure the range will be good enough

- https://www.amazon.com/FrSky-Access-900MHz-MM-OTA-Receiver/dp/B07VT2HCTV/ref=sr_1_1?dchild=1&keywords=frsky+r9mm&qid=1589921527&sr=8-1

- Runcam Micro Swift 3

- Buzzer with LiPO battery

Photos

Part List

Frame |

Team-blacksheep.com

(105 builds)

Team-blacksheep.com

|

See Site |

Flight Controller |

Matek F405-CTR 30x30 Flight Controller

(34 builds)

Racedayquads.com

|

$39.99 |

ESCs |

4X HAKRC BLHeli_32 Bit 35A 2-5S ESC Built-in LED Support Dshot1200 Multishot for FPV RC Drone

(14 builds)

Banggood.com

|

$39.51 |

Motors |

4 x Home

Buildyourowndrone.co.uk

|

See Site |

Propellers |

DJI Original 9'' CW+CCW Props 9450 Self-tightening Propeller 4 Pcs for Phantom 3 Professional / Advanced / Standard Quadcopter

Amazon.com

|

$16.99 |

FPV Camera |

Runcam Micro Swift 3 4:3 600TVL CCD Mini FPV Camera 2.1mm/2.3mm PAL/NTSC OSD Configuration

(25 builds)

Banggood.com

|

$35.99 |

FPV Transmitter |

Eachine TX805 5.8G 40CH 25/200/600/800mW FPV Transmitter TX LED Display Support OSD/Pitmode/Smart Audio

(15 builds)

Banggood.com

|

$12.90 |

Receiver |

FrSky R9MM Long Range 915MHz RC Receiver - Get Yours Today! - RMRC

(114 builds)

Readymaderc.com

|

$20.80 |

Guides & Reviews

AirbladeUAV has done it again and this time they've brought long range to the 5" class! Based on the popular Transformer Mini, the new Transformer 5" Ultralight adopts a lot of the same design philosophies with larger props and more payload capacity. It can fly upwards of 20 minutes on a 4 cell Li-Ion battery pack and in ideal conditions it's got a range of over 4 to 5 miles. In this guide I'll walk..

Read moreWith the release of the DJI FPV Drone cinematic FPV has become a lot more accessible, but you certainly don't want to crash a $750 drone! The QAV-CINE Freybott is a compact, lightweight cinematic FPV drone that can take a hit and keep going. It's a lot safer to fly indoors and around people. With a naked GoPro or the SMO 4k you can capture some great stabilized footage. In this guide I'll show you..

Read more

New Message for L3M4R