Slim Jim

By Craftedkwads on Jun 18, 2020

By Craftedkwads on Jun 18, 2020

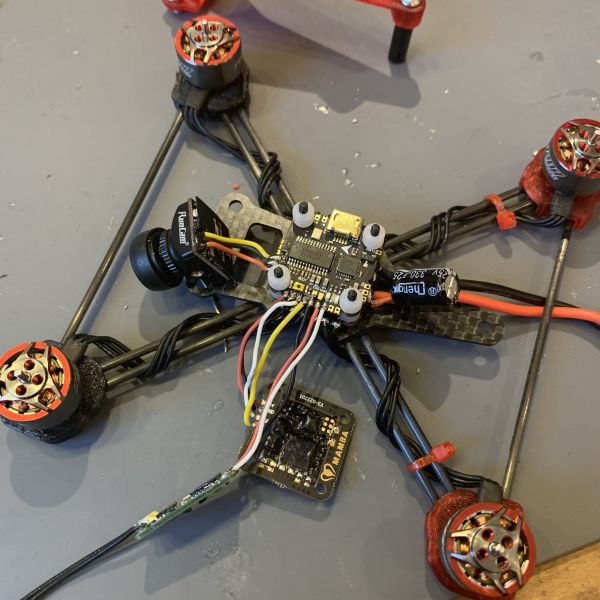

This is a experimental frame that I've been working on for a bit. It consists of 3d printed parts, 2mm carbon fiber rods, and optional machined plates. It is definitely not a ultralight, weighing in at 25g with hardware. It flies very well, the Rcinpower 1207 motors are super smooth and powerful, but the metal is super soft and dents and dings super easily. Already I've had to take them apart to un-dent the bell after small crashes. In regards to the carbon fiber rods, the frame is super strong. The weak spot is the 3d printed body, as I'm printing in abs. Sooner or later I will get polycarbonate or NylonX to print with, but as of now the expense of NylonX is not justifiable for this, and polycarbonate would require a hotend rework, something that I am not looking forwards to and is a extra expense. Flight time is between 2-4min, depending on how hard I fly.

This project is one of the more interesting I've take on over the past few months. The frame has gone over 85 versions and revisions, as I worked to optimize it for ease of assembly, clean look, and component space. The frame is setup to take a 16x16mm stack, nano camera, and 9mm mounting motors. Why 16x16? I chose a 16x16 stack for multiple reasons;

- I really hate AIO boards. If a esc blows or a flight controller dies, you have to resolder every component and buy a new board, which is more expensive than getting only the part that died. With 16x16, if a esc blows, you only have to spend money on the esc and resolder the esc joints, limiting the space for error while soldering and reworking boards.

- It fits the frame profile better. With nano sized components, rework and disassembly is a pain. With this style frame, you can see all the components while still having space to add more. additionally, the frame can be narrower, which I like the looks of.

- Ease of access. Most of the solder joints are accessible without taking it apart, so a motor swap is easy, and diagnostics as well. The usb port is in the open, and their is room to get to other components as well.

A receiver fits inside the canopy above the stack, and a capacitor fits behind the stack as well. With the rod design, you can choose your own frame size and prop size, meaning that theoretically, you could setup this frame for 2" props all the way up to 5" (not recommended). The frame fits together friction tight, but I chose to superglue the parts together for added security. The price of a single frame costs $1-$3, depending on the price of carbon and filament. Motors are softmounted as well, but those can be removed to make it lighter. Overall, it was a very enjoyable build, and one that I will be releasing if anyone wants it. I call it the Slim Jim, as the individual rods are like Slim Jims, and the configuration resembles a slimjim antenna. Slim Jim FTW!

UPDATE: All files have now been released on Thingiverse!

Photos

Part List

Flight Controller |

Diatone Mamba F411 Nano V1.2 2-4S 16x16 Stack/Combo (F4 FC / 13A ESC)

(7 builds)

Racedayquads.com

|

$39.99 |

Motors |

4 x RCINPOWER GTS V2 1207 5000/6000KV 3-4S 7500KV 2-3S Brushless Motor for RC Drone FPV Racing

(10 builds)

Banggood.com

|

$43.20 |

Propellers |

HQ Prop T3X2 Bi-Blade (CHOOSE COLOR)

(14 builds)

Pyrodrone.com

|

$1.89 |

FPV Camera |

RunCam Nano2 1.8mm Lens

(184 builds)

Heli-nation.com

|

$19.99 |

FPV Transmitter |

TBS Unify Pro32 Nano 5G8 V1.1 VTx Video Transmitter

(401 builds)

Pyrodrone.com

|

$37.99 |

Antenna |

Lumenier Micro AXII Shorty U.FL 5.8GHz Antenna (RHCP)

(36 builds)

Pyrodrone.com

|

$19.99 |

Receiver |

FrSky XM+ 2.4GHz Micro ReceiverDefault Title

(1151 builds)

Racedayquads.com

|

$15.99 |

Batteries |

RDQ Series 11.4V 3S 525mAh 80C LiHV Micro Battery - XT30

(14 builds)

Racedayquads.com

|

$11.74 |

Misc Parts |

Forever Antenna Tube 2 Pack - Choose Your Color

(13 builds)

Racedayquads.com

|

$2.99 |

Guides & Reviews

AirbladeUAV has done it again and this time they've brought long range to the 5" class! Based on the popular Transformer Mini, the new Transformer 5" Ultralight adopts a lot of the same design philosophies with larger props and more payload capacity. It can fly upwards of 20 minutes on a 4 cell Li-Ion battery pack and in ideal conditions it's got a range of over 4 to 5 miles. In this guide I'll walk..

Read moreWith the release of the DJI FPV Drone cinematic FPV has become a lot more accessible, but you certainly don't want to crash a $750 drone! The QAV-CINE Freybott is a compact, lightweight cinematic FPV drone that can take a hit and keep going. It's a lot safer to fly indoors and around people. With a naked GoPro or the SMO 4k you can capture some great stabilized footage. In this guide I'll show you..

Read more

Did you ever checked a BlackBox log for frame vibration frequencies?

I did not- the stack I use unfortunately unfortunately does not have blackbox. however, regular flight (through dvr, controls, and sound) lead me to believe that it is solid and doesnt have a insane amount of vibrations over a standard frame.

I have seen your other builds and share your opinions about 16mm stacks. Maybe have a look at the Flywoo Goku, comes with BB.

Thanks

Yes! my esc actually popped and unfortunately burned my fc too, so Im getting a new stack and possibly designing a new frame ;) glad there are others who share the stack over aio opinion, I know its not the most popular.