This Quad is Decommissioned

I could never get it tuned well. I suspect the never versions of BF do not like V-Tails.

MICRO - V-Tail - TRASHED

I always loved the more unique types of multirotors especially V-Tails! I never tried flying one thuogh..

Also i do not have much space where I live so micros and whoops are more my kind of thing.. Finding a modern 2-3in V-tail frame is not easy.. V-tails also seem like a dying breed..

BUT I do not take no for an answer!

So this will be my first custom frame!! :D

Some design goals:

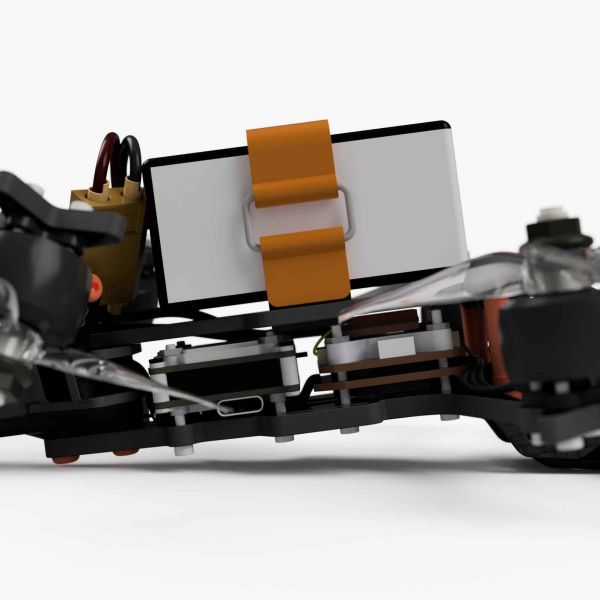

-A powerfull 3" V-Tail build for reckless flying.

-Keep COG as close to propeller plane as possible.

-Keep weight destribution as compact as possible

-No structural parts made of 3D print!!!

-Slightly rearward pointed tail motors for increased forward speed at reduced pitch.

-Prop free view

Micro size cameras

Room for Caddx Vista

Design trashed because the bewer versions of BF does not really support V-tails.. ANd it was way to heavy..

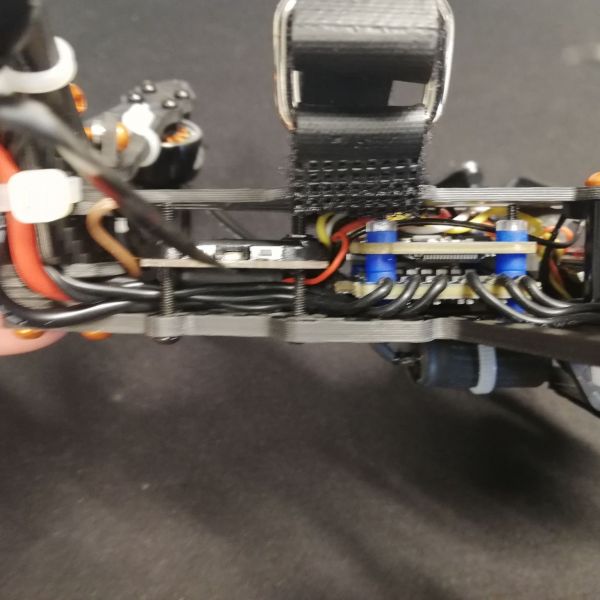

Photos

Part List

Show stores (7)Dude

That's such a cool idea

I build a big one

https://rotorbuilds.com/build/11629

flew awesome, yaw authority is superb, watch this

and do notice what he says about the rear motor angle

if you go for 45 degrees, it does not fly that well

30 - 35 degree angle for rear motors is ideal, just take it into consideration

I mean, the guy (simplecopter) experimented

Big thumbs up and I definetily want one of the frames

I'll pimp it like I always do, check my profile

Guides & Reviews

AirbladeUAV has done it again and this time they've brought long range to the 5" class! Based on the popular Transformer Mini, the new Transformer 5" Ultralight adopts a lot of the same design philosophies with larger props and more payload capacity. It can fly upwards of 20 minutes on a 4 cell Li-Ion battery pack and in ideal conditions it's got a range of over 4 to 5 miles. In this guide I'll walk..

Read moreWith the release of the DJI FPV Drone cinematic FPV has become a lot more accessible, but you certainly don't want to crash a $750 drone! The QAV-CINE Freybott is a compact, lightweight cinematic FPV drone that can take a hit and keep going. It's a lot safer to fly indoors and around people. With a naked GoPro or the SMO 4k you can capture some great stabilized footage. In this guide I'll show you..

Read more

So whats the advantage here compaired to a normal quad?

Theoretically the advantage is more yaw authority.. Not sure i ever felt like i needed more yaw authority on nowadays quads though xD

Also the slight backwards angle will also give forward speed without as much tilt..

It is slightly less efficient though..

But to be honest.. It just looks cool xD

Just like your micro tri-copters! Love those!

You should build a 3" Whirlygig with 1103-10000kv motors @ 2S. Its performance will surprise you and definetly would be something unique to add to your collection.

This week i will start builing an inverted 3" Whirlygig with 1104-4500kv motors @ 4S. I had made one previously but sold it shortly after performing the base tune. (Its on Rotorbuilds) The little copter flew like a bat outa hell, even with its motor scaling set to 50%.

Oh yes i saw the video of that one! Or was it the normal one?

But I sure will get me a micro tricopter as well Once the V-Tail is flying!

I really like yours!

Most of the videos are of the 2S Whirlygigs. Their very light and pretty simple to build as the Servo can directly connect to the Lipo. (16v 100 uf capacitor added in-line for filtering) Hence with the direct-connect, it removed the need for the secondary 7.4V BEC's used on the 4S builds.

I beleive theres still a video of the 4S on YouTube from last year. Though to be honnest, I was a bit disapointed with the 4S results. Simply put, the 1st 4S had a crappy camera that I wanted to step away from but flew like a missle @ 30% motor scaling. (Hard to control at that speed) The 2nd 4S with Emax 1106 motors (6-7 grams each) was overly heavy and thus tended to over-draw the battery when taken above 50% throttle. The 3rd build (Sold this one) with Emax 1108 motors (7-8 grams each) had a similar issue around 60-70% throttle but is much lighter overall. Despite this, all the builds had an ungodly TWR for such little things. (7 or 8:1 TWR) Saying this made tuning quite a challenge would be an underestatement. (They litterally scream at higher throttle settings)

V1 4S Whirlygig: https://rotorbuilds.com/build/18331

V2 4S Whirlygig: https://rotorbuilds.com/build/18949

V3 4S Whirlygig: https://rotorbuilds.com/build/20766

With the upcomming build, I'm hoping that the Xing 1104 motors will do the trick this time around as they have a much lower current draw and come in at 4-5 grams each. Its possible that change from the Emax mini 3" props to 2-bladed 3025's would help as well. Those 3025's are what I currently use on the 2S builds but I fear that using them with the 4S would cause the props tp flex horribly at full throttle.