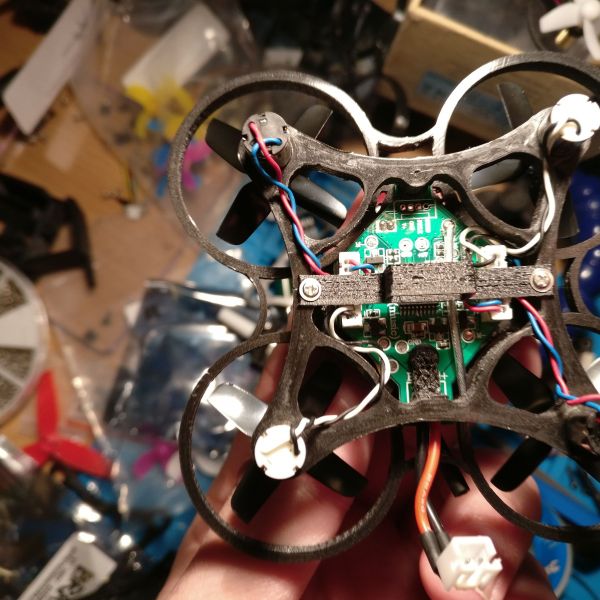

So this was basically my race whoop for half of last years season before upgrading to an alienwhoop zer0 which I will post later.

Sorry for the late upload but after the orqa dvr video dropped lots of people asked about the cam and whoop so I decided to quickly add a write up.

The Frame

Anyway this is once again based on the awesome frame designs of rockracer

I modified the design a bit to reduce weight mostly and:

- integrate the cam mount into the duct part of the frame

- used the same modified canopy as on my 0603 brushless whoop

- reduced the height of ducts and base frame to save weight

- used a custom designed battery mount to keep the lipo secure

I can upload my stls if anyone cares otherwise just head over to rockracer and grab a flavor you like - hes got plenty in terms of different sizes and brushed/brushless versions.

The FC

It's a Boldclash CM03 but it's basically the same thing that comes with the banggood santa whoop or E011 10$ whoops.

Firmware / Silverware

This is running silverware which performs great on whoops. Also means no OSD unless you do a complicated build with external OSD module (I did this - article is coming soon :-D )

Weight is about 24g

3d-Printing

Printed out of Nylon CF15 a Nylon Carbon Fiber compound which was pretty reliable. Eventually I broke some ducts which i taped up in the DVR below as I haven't had time to swap the ducts yet.

Also I have since moved on to PCMAX in terms of whoop filaments.

DVR (60fps ORQA)

Make sure to watch it at least in 1080p/60fps

If you are wondering why the DVR looks so great, its recorded on my orqa goggles after the latest firmware update.

As I said one of the ducts is tapped after flying this for half a year so nevermind it please :-D

Photos

Part List

Show stores (7)Hey...did you try using TPU filement for the 3d print yet?...becuase of the flex its and more crash resistant.

Yeah I did - don't like it.

It's heavier (TPU is hygroscopic and will draw water from the air to be flexible) and most of all not as stiff leading to decreased flight characteristics.

Also for the ducts specifically it would require more walls to make the ducts not super floppy and that would make the frame much heavier.

Best is PCMAX so far followed by Nylon/Carbon, followed by Nylon and then ABS.

Pure Nylon is annoying to print tho.

Certainly better than PLA, about on par maybe a little better than ABS but below Nylon,Nylon Compounds and PCMAX. ABS has the advantage that you can just glue/fix broken stuff with a bit of aceton which won't work for PETG. PETG has the advantage that its easier to print if you don't have an enclosure due to warping. PETG might be to flexible for the ducts on this design tho as they are very thin. I tried some PETG/Carbon mix filament and didn't like it at all.

so wait the boldclash board is compatible with frsky?

I am using the irx4 multiprotocol modul to communicate with the bayang rx on the boldclash fc (which is awesome, lower latency than crossfire and you get telemetry too).

Alternatively you can just use the 12$ lite module from betafpv e.g. https://betafpv.com/collections/rx-tx/products/litemodule-bayang-rf-module

But to be honest I'd recommend just getting the irx, it's about 36$ without coupons and stuff and will basically run anything 2.4ghz (frsky/flysky/dsmx/bayang etc.) - well worth the investment for the flexibility.

Guides & Reviews

AirbladeUAV has done it again and this time they've brought long range to the 5" class! Based on the popular Transformer Mini, the new Transformer 5" Ultralight adopts a lot of the same design philosophies with larger props and more payload capacity. It can fly upwards of 20 minutes on a 4 cell Li-Ion battery pack and in ideal conditions it's got a range of over 4 to 5 miles. In this guide I'll walk..

Read moreWith the release of the DJI FPV Drone cinematic FPV has become a lot more accessible, but you certainly don't want to crash a $750 drone! The QAV-CINE Freybott is a compact, lightweight cinematic FPV drone that can take a hit and keep going. It's a lot safer to fly indoors and around people. With a naked GoPro or the SMO 4k you can capture some great stabilized footage. In this guide I'll show you..

Read more

Hi, any chance you can upload your STL of the wieght savins please?